Nmrv Worm Gear Reducer

Nmrv worm gear reducer,it's small in volume,light weight,high in radiating efficiency,large in output torque,smooth in running and low noise. It's suitbale for all positions.

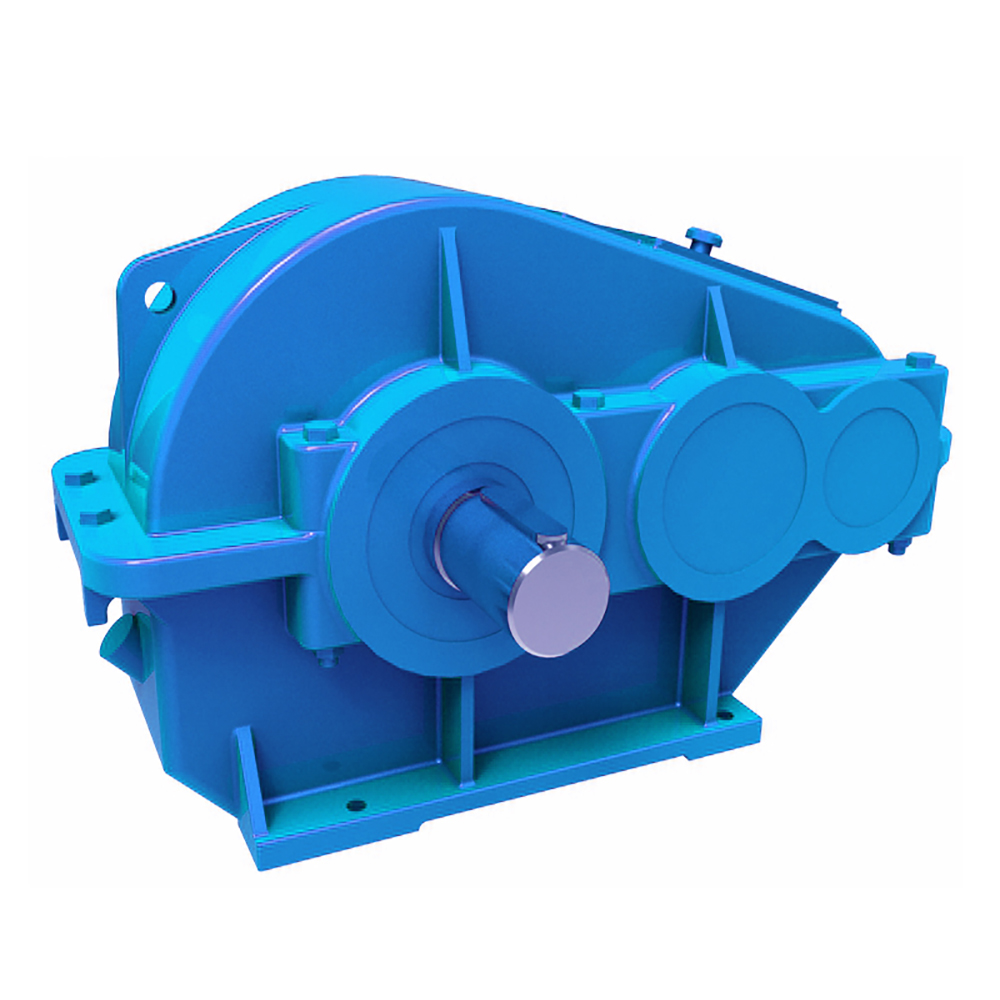

Gear Reducer

R series helical gear reducer is an advanced design concept introduced from abroad in recent years. It is developed and manufactured with reasonable structure, strong versatility, high reliability, low temperature rise, large bearing capacity and good combination performance in combination with the objective reality of our country. It can be combined with F series, K series, S series, etc. to obtain lower speed and greater torque.

OUR LATEST PRODUCTS

ABOUT US

Jiangsu Devo Gear Technology Co., Ltd. was founded in 2018. It was founded by a group of young people with enterprising spirit. It is determined to make a good gear box in 100 years. The company is 50-100 people, with professional R&D, design, sales team, products sell well at home and abroad, the market is mainly concentrated overseas.Provide customers with personalized solutions.On the basis of reciprocity and mutual

Play gambling at roxcasino.com. Good bonuses, fast payments, convenient design. Every fan of gambling will appreciate the possibilities of the service roxcasino.com.

Register on the website JoyCasino and get a welcome bonus of 200 freespins. Great bonuses await users on the official site of JoyCasino.

Vavada Casino – the most popular gambling service on the Internet. The site for the past year is very popular with players and takes the top ratings of online casinos. Come and find out what the Vavada gambling site has to offer.

Play slots for money and win jackpots at Casino X. Tired of slots? Play live games with live dealers. Every gambling lover can find an activity to their liking at Casino X.

Play for money and win at Jozz Casino. And for new players, the site has prepared a welcome bonus of +100% to the amount of the first deposit. Play gambling with comfort with bonuses Jozz Casino.