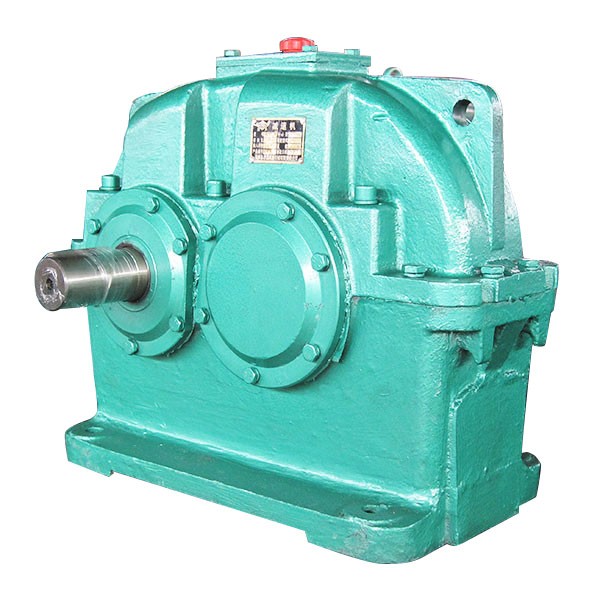

ZDY Series 1 stage ZDY 80 hardened gear surface cylindrical gearbox for metallurgy industry

- Place of Origin:

-

Jiangsu, China (Mainland)

- Brand Name:

-

DEVO

- Gearing Arrangement:

-

Cylindrical gear

- Output Torque:

-

0.36-154.6 KN.m

- Input Speed:

-

750-1500 rpm

- Output Speed:

-

134 -1200 rpm

- Product name:

-

ZDY Series Gearbox

- Housing material:

-

cast iron

- Material of bearing:

-

steel

- Heat treatment:

-

Quenching

- Mount Position:

-

Horizontal

- Application:

-

Metallurgy

- Warranty:

-

1 Year

- Certification:

-

ISO9001

- Packing:

-

Wooden Case

- Color:

-

Red, Green, Blue or customized

Packaging & Delivery

- Selling Units:

- Single item

- Single package size:

- 29X20X26 cm

- Single gross weight:

- 300.0 kg

- Lead Time :

-

Quantity(Piece) 1 – 10 >10 Est. Time(days) 15 To be negotiated

Introduction of the ZDY series

ZDY Series One stage surface hardened Cylindrical Gear Gearbox, are suitable for high-speed axle with a speed less than or equal to 1500 rpm. The gearbox has a hard tooth surface with thrust bearing and very high precision. With the features of using alloy steel with high strength to produce its accessories such as gears and axle.

Parameter table of ZDY series products

Dimension figure of ZDY series

Use and maintenance

(1) The lubricating oil should be filled into the oil tank of the housing which is between the two oil screws; when the

filling is finished, the reductor could run with load upon the only condition that the stability of operating is confirmed

after the equipment runs without load for a while.

(2) The suitable brand of the lubricating oil: 150 # industrial gear oil being used in the summer 120 # industrial gear oil

being used in the winter; if the industry gear oil above are in lack of, both the 50# gear oil in summer and the 40# gear

oil in winter can be used instead.

(3) The inside of the reductor should be washed once at least within the first six months after it being used and then

the lubricating oil should be refilled.

(4) The reductor under the circumstance of normal operation should be maintained regularly. According to the

operating conditions and concrete situations, a thorough maintenance should be implemented every 6 to 12 month.

Below come the details of the maintenance: Open the cover board of the peephole, then check the state of friction of

every gear. The lubricating oil should be checked carefully, if the emulsification of the lubricating oil is being

discovered, the whole emulsion oil must be drained out and the gears should be washed by light oil, finally refill the

housing the new oil.

If the reductor doesn’t restore to work right away, then the oil extractor has to operate 10 minutes at least which

assurances the lubricating film being originated on the surface of gears and bearings of the reductor.

(5) If the bearings are lubricated with the grease, the type ZL-3 should be used in the summer and the ZL-2 lithium grease should be used in the winter, the grease should be refilled every six month.